Rotors are crucial for fleet truck winches in Brownsville, providing essential torque and performance. Optimizing equipment effectiveness involves selecting robust rotor designs tailored to heavy-duty applications. Regular maintenance, including inspections, cleaning, lubrication, and tire pressure checks, extends rotor lifespan. Well-maintained rotors enhance productivity, vehicle stability, and safety during demanding tasks like towing and lifting heavy loads in dynamic environments like Brownsville.

In the world of fleet truck winches, Brownsville, TX, is known for its robust heavy-duty machinery. Central to these machines are rotors, which play a pivotal role in ensuring optimal performance and safety. This article delves into understanding rotors, exploring different types used in Brownsville’s fleet trucks, offering maintenance tips, and analyzing their impact on performance and safety. By understanding these key components, fleet operators can maximize efficiency and minimize downtime.

- Understanding Rotors: Their Role in Fleet Truck Winches

- Types of Rotors Used in Brownsville's Heavy-Duty Machinery

- Maintenance Tips to Keep Your Truck's Rotors in Top Shape

- The Impact of Rotors on Performance and Safety in Fleet Operations

Understanding Rotors: Their Role in Fleet Truck Winches

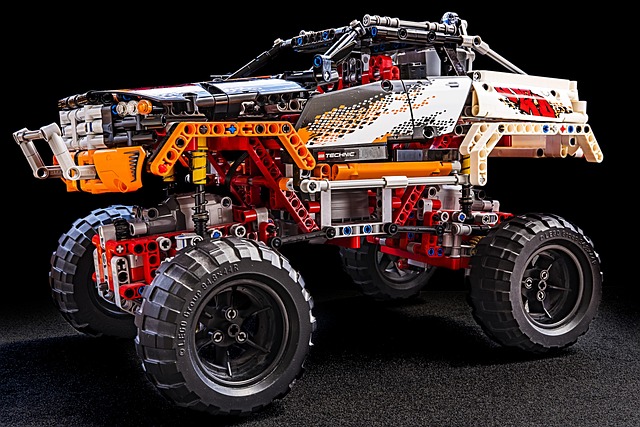

Rotors play a pivotal role in the efficient operation of fleet truck winches in Brownsville. These rotating components are responsible for generating the necessary torque to lift and move heavy loads, making them an integral part of any vehicle’s lifting system. In the context of fleet truck winches, rotors enable swift and powerful operations, ensuring that vehicles can be quickly towed or lifted in various emergency or maintenance scenarios.

Understanding the mechanics behind rotors is crucial for optimizing performance and longevity. The rotational force they produce allows for smooth and controlled movement, preventing sudden jolts or strains on other components. This is particularly important in fleet settings where frequent use and diverse terrain conditions can put a strain on winches. By choosing robust rotor designs tailored to the specific demands of fleet truck winches, operators in Brownsville can enhance overall equipment effectiveness and reduce maintenance needs.

Types of Rotors Used in Brownsville's Heavy-Duty Machinery

In Brownsville, heavy-duty machinery operates across diverse industries, demanding robust and reliable components like rotors. One prominent type is the drum rotor, commonly found in fleet truck winches. These rotors are engineered for high friction capabilities, enabling efficient towing and lifting operations. Their design incorporates advanced materials to withstand intense heat and pressure, ensuring optimal performance during strenuous tasks.

Additionally, disc rotors have gained popularity for their versatility. Used not only in truck winches but also in various industrial applications, these rotors offer superior cooling efficiency due to their larger surface area. This feature is crucial for maintaining consistent performance in demanding environments, making them a preferred choice for Brownsville’s heavy-duty machinery fleet.

Maintenance Tips to Keep Your Truck's Rotors in Top Shape

Maintaining your truck’s rotors is essential for ensuring optimal performance and safety, especially for those operating fleet trucks in demanding environments. Regular inspection and timely maintenance can significantly extend the lifespan of your rotor components. One key tip is to regularly check for signs of wear, corrosion, or damage during routine washes or inspections. Addressing any issues promptly will prevent minor problems from escalating into costly repairs.

For fleet truck owners in Brownsville, prioritizing rotor care is crucial due to the city’s diverse terrain and frequent use cases involving heavy-duty winches. Consistent cleaning and lubrication are simple yet effective practices. Use specialized cleaners to remove brake dust and corrosion, followed by a light coating of lithium grease or similar lubricants. Additionally, keeping an eye on air pressure in tires can reduce braking stress, thereby prolonging rotor health. Regular service intervals with a trusted mechanic familiar with fleet vehicles will further ensure your truck’s rotors remain in top shape.

The Impact of Rotors on Performance and Safety in Fleet Operations

In fleet operations, rotors play a pivotal role, significantly influencing performance and safety, especially in vehicles equipped with truck winches in Brownsville. These rotating components are integral to the operation of winches, which are essential for tasks like towing, lifting, and moving heavy loads. High-quality, well-maintained rotors ensure smooth and efficient power transmission, directly translating to improved fleet productivity.

The impact extends to safety, as robust rotors contribute to the overall stability and control of vehicles during demanding tasks. In the case of truck winches, reliable rotors minimize the risk of failure, ensuring operators can complete jobs securely and effectively. This is particularly crucial in dynamic environments where fleet trucks in Brownsville frequently navigate challenging terrain or handle emergency situations, underscoring the critical role rotors play in maintaining both performance and safety standards.

Rotors play a pivotal role in the performance and safety of fleet truck winches in Brownsville. By understanding their function, choosing the right types for heavy-duty machinery, and implementing effective maintenance practices, operators can ensure optimal performance and enhanced safety during operations. Regular care and attention to these critical components are essential for maintaining efficient fleet operations, ultimately contributing to a smoother and more secure working environment.